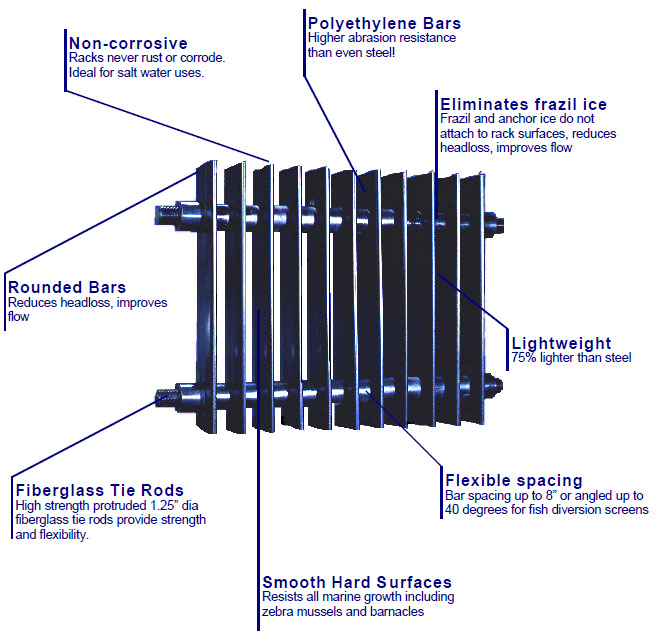

Features

- Streamlined blades

- Fish friendly

- Lightweight (75% lighter than steel)

- Eliminates frazil ice problems

- High load capacity

- Resists marine growth

- Reduces headloss

- Non-corrosive

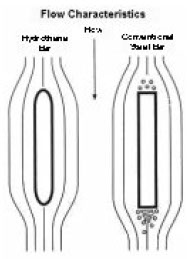

Reduced Headloss

The vertical blades in a Hydrothane Trashrack are styled after U.S. Navy torpedo designs with rounded leading and trailing edges. This proven aerodynamic design reduces resistance to flow in the front and rear of the rack. The smooth blade surface cuts frictional resistance across the blades.

This results in a significant improvement in flow efficiency through the rack itself. Tests and field results have shown the Hydrothane design to cut headloss in half with trashrack bar spacing of 3” (76 mm) or less. This also results in a more fish friendly trashrack.

Visit our Online Documentation to view a pdf file of flow tests conducted on Hydrothane trashracks.

General Construction

Over 800 installations in the USA & Canada All Hydrothane Trashracks consist of four (4) basic components. Assembly is simple, fast and the low weight of the racks shows up in lower installation costs.

+

Vertical Blades

Composed of high tensile, high load bearing, abrasion resistant virgin polymers (Extra High Molecular Weight Polyethylene) with added strengthening agents. Hydrothane’s employs a unique profile molding process to assure material consistency and quality throughout. Material chemistry includes 2% carbon black for superior UV protection.

+

Horizontal Tie Rods

Produced from ultra high strength protruded fiberglass rod. Our rods allow the rack to flex with high loads yet return to the original form after the load is released. Rods are 1- 1/4” (32 mm) with a smooth unmachined mid section and threaded ends.

+

End Nuts

Injection molded nylon with a tapered internal thread. The end nuts will self-tighten as they are screwed in place. Once in water the end nuts will absorb a small amount of water to expand and lock into place on to the tie rod. No need for additional set pins or other positive means of fixation.

+

Installation

As with any water intake installation, adequate horizontal support beams must be present or the racks can be mounted to a frame and slid into place. Hydrothane design engineers will advise you on specifics of support structure. The racks are bolted to the supporting structure using U-Bolts, welded plate or other means of positive fixation.

+

Blade Spacers

Protruded EHMW Polyethylene tubes cut to the customer’s specifications for blade clearance.